Top Guidelines Of Steel Road Plates

Top Guidelines Of Steel Road Plates

Blog Article

The Basic Principles Of Steel Road Plates

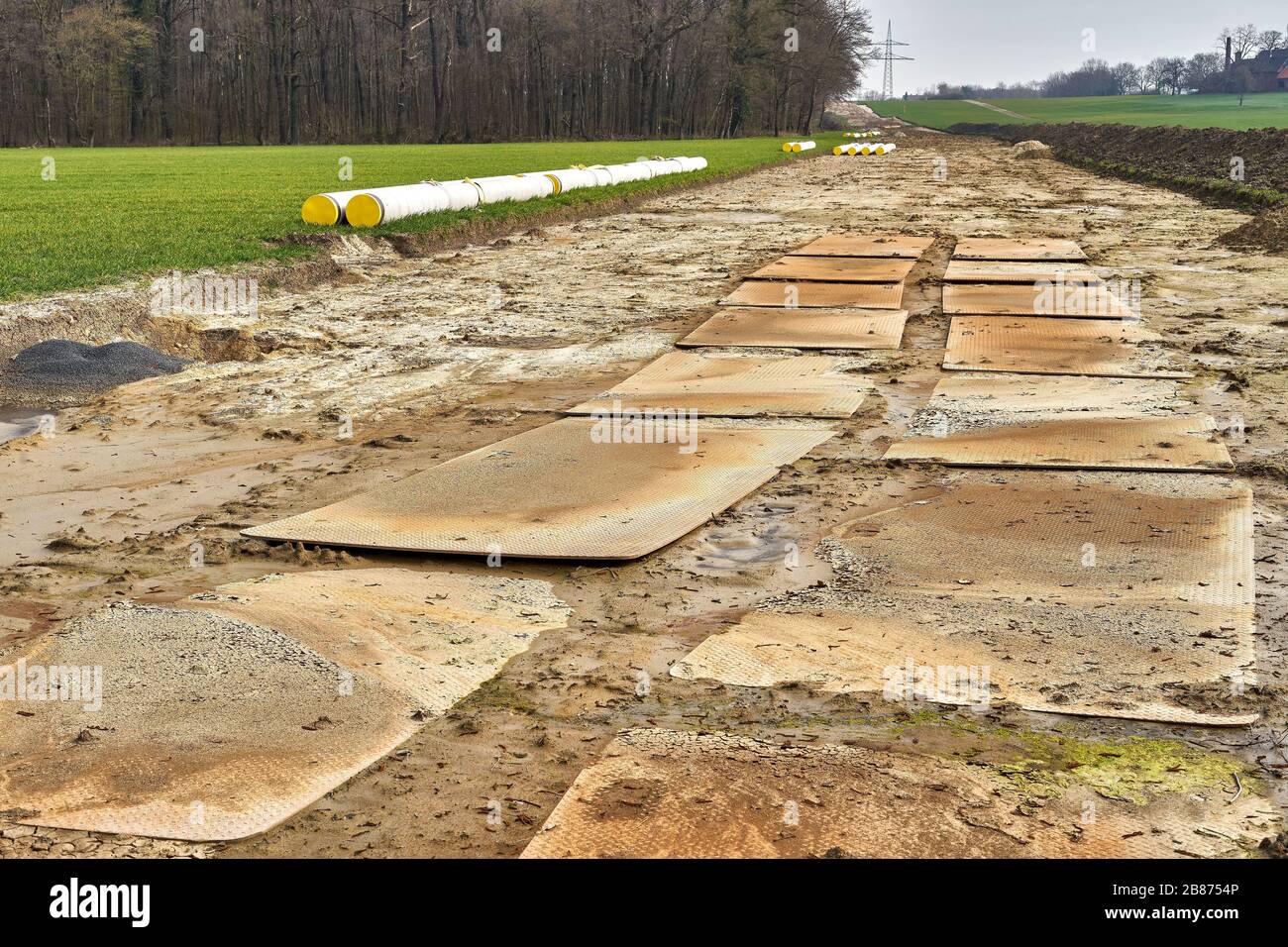

Steel layers are give a great, short-lived remedy for covering harmful openings on a building and construction site. These durable, robust plates enable roadways to return to service to ensure that building and construction can continue. Right here we check out the layout information and best method installation suggestions. These plates can be made use of to guarantee that roadways can still be used whilst other stages of job proceed.

They are commonly seen when excavations have actually started as an early phase of construction or fixing jobs. These plates are made to hold up against durable usage on busy roadways.

The weights begin from about 300kg and typical roadway plates have a thickness of either inch or inch. We can additionally provide customised dimensions. The essential features of the item are as adheres to: Openings to enable for secure add-on to lifting plants. The capability to be bolted to the road.

How Steel Road Plates can Save You Time, Stress, and Money.

Hinged versions for fast accessibility to the excavation or regular access, e.g. driveways. Composite plates, which can accommodate different sizes of trench. Skid-resistance for boosted vehicle, pedestrian and site worker security. Steel road plates can be mounted fairly promptly, however they are heavy. Because of this, they should be installed making use of a forklift or crane.

Look for variation by traffic filling from the start plates need to constantly stand up to variation. Inspect that the plates do not offer a hazard to any kind of sort of road user and can be utilized by all roadway customers and automobile types, including pedestrians, bikers and motorcyclists. Create a regular inspection and maintenance to ensure that performance continues to be risk-free and maximum.

Deal with the plates properly at all times. Mechanical lifting makes sure that the plates are mounted properly and securely.

If a ramp is developed by the roadway layers, then cautioning indications for pedestrian and road individuals are called for. Always a conduct complete website study, and take the professional guidance of a structural designer.

Steel Road Plates for Dummies

In order to enhance security, there are a number of standards and sector files assisting their use in building and construction job zones. Steel plates have to be taken care of in area to stay clear of activity.

Steel Road Plates for Dummies

Along with being firmly in contact with the pavement, they need to be either pinned, check these guys out recessed into the sidewalk, or secured with asphalt wedges around the border. Pinning into the pavement involves driving pins into the sidewalks along the edges of the steel plates to avoid activity. Recessing includes removing the location where the steel plate will certainly be placed.

This results in the steel plate being flush with the pavement. Furthermore, when numerous steel plates are made use of and butt approximately each other, they should be bonded with each other at the longitudinal joints. Steel plates can be extremely slippery, particularly when they are wet, unless they have an anti-skid finishing used.

Covering steel layers with a material that raises friction helps motorcyclists and bicyclists retain control, particularly in wet weather condition. Problems which minimize sidewalk rubbing in job zones are of particular issue to motorcyclists and bikes. A common threat in steel plate installations occurs when the individual falls short to construct appropriately tapered ramps from the street to the sides of the steel plate( s).

Rumored Buzz on Steel Road Plates

It presents a significant risk to motorcyclists and bicyclists that can quickly shed control when they speak to the abrupt/steep tapered ramp and the steel plate. Appropriately tapered ramps allow users to safely cross over the steel plates.

Make sure ample overlap. Generally, steel plates need to prolong at the very least one foot past the sidewalk opening onto firm ground.

Steel Road Plates Can Be Fun For Anyone

Welding is utilized when even more than one steel plate is used and they butt up to each other. Plates have to be countersunk when needed due to unequal highways.

His background includes the building and construction, inspection, read even more.

Worldwide of civil informative post engineering and building, steel roadway plates are a perfect tool that holds immense relevance. These durable steel plates play an essential role in enhancing building and construction security, providing short-term roadways, and making certain smooth procedures on various job sites. As a construction tools supplier, their value can not be overemphasized.

Report this page